Kinetic Metallization: High Dynamic Range

HDR Next Generation Coating System

Inovati’s new High Dynamic Range (HDR) system is more compact and user friendly than ever before. System improvements include, but are not limited to; a miniaturized control cabinet, new gas control systems, and a redesigned powder feeder for improved performance and convenience. Hardware used for kinetic metallization is designed to provide the operator maximum control, as most of its parts are adjustable and can control the deposition of material. In comparison to competing technologies, KM hardware consumes less gas and still yields high particle velocities due to its reliance on low pressure and sonic gas speed. Such attributes make kinetic metallization the safest cold spray technology on the market, as it permits the deposition of potentially hazardous material with minimal to no risk at the expense of either operator or machine. The KM-HDR has been redesigned from the ground up to bring improvements to every aspect of the technology compared to competing technologies as well as the previous 4th generation KM systems.

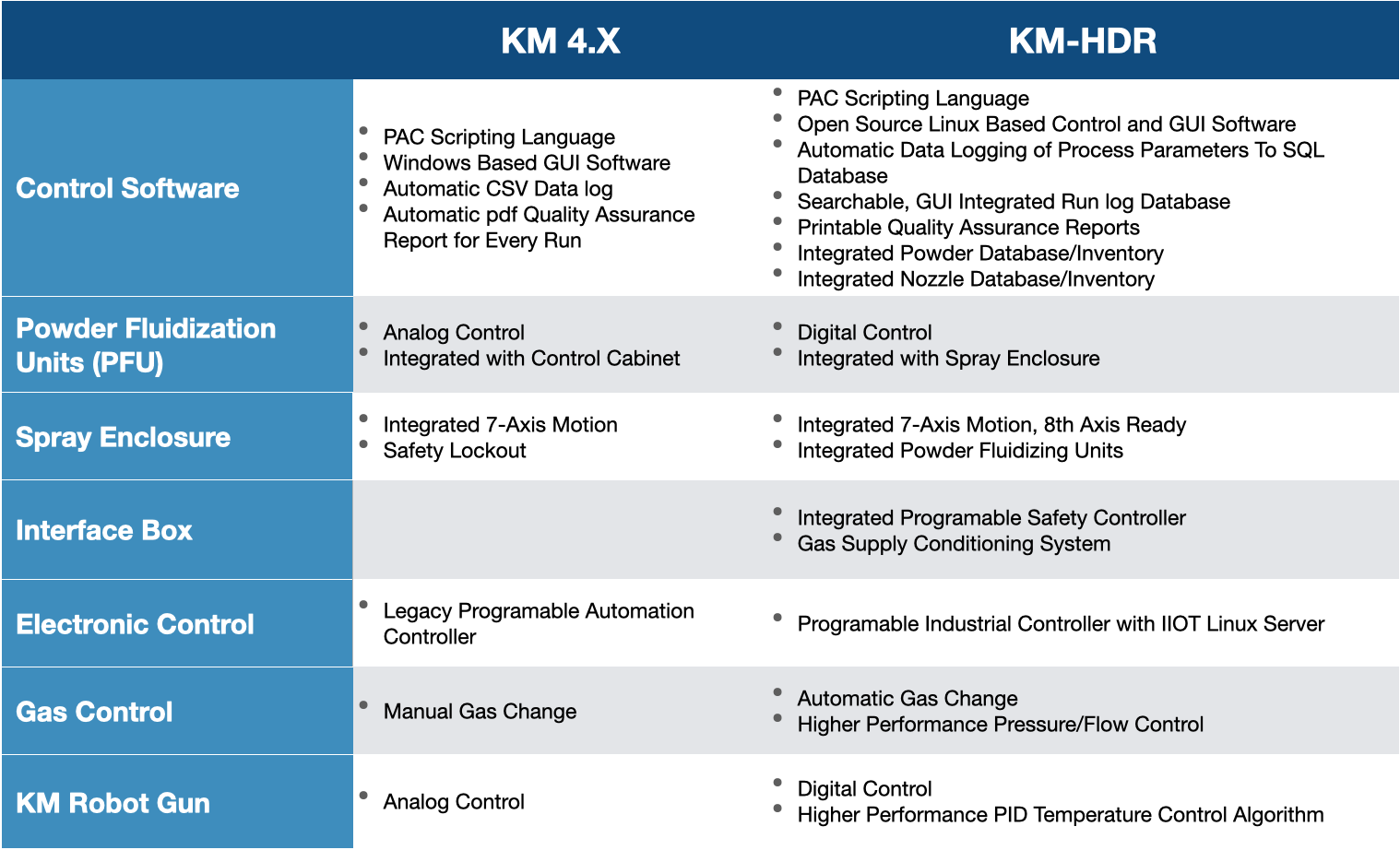

Gen 4 vs HDR

Control Cabinet

The new highly compact system houses all gas and electrical control systems in a 16x18” UL-508 enclosure. The next generation control system features all new hardware and greatly improved performance and functionality over previous generation Kinetic Metallization and Cold Spray systems. Features include:

- • High performance electronic pressure and mass flow controllers

- • Improved digital temperature control algorithm

- • Automatic switching between He, N2, and He/N2 mixture

- • Startup initiated system health monitoring

- • Real-time process automation controller

- • Automatic logging of all process parameters

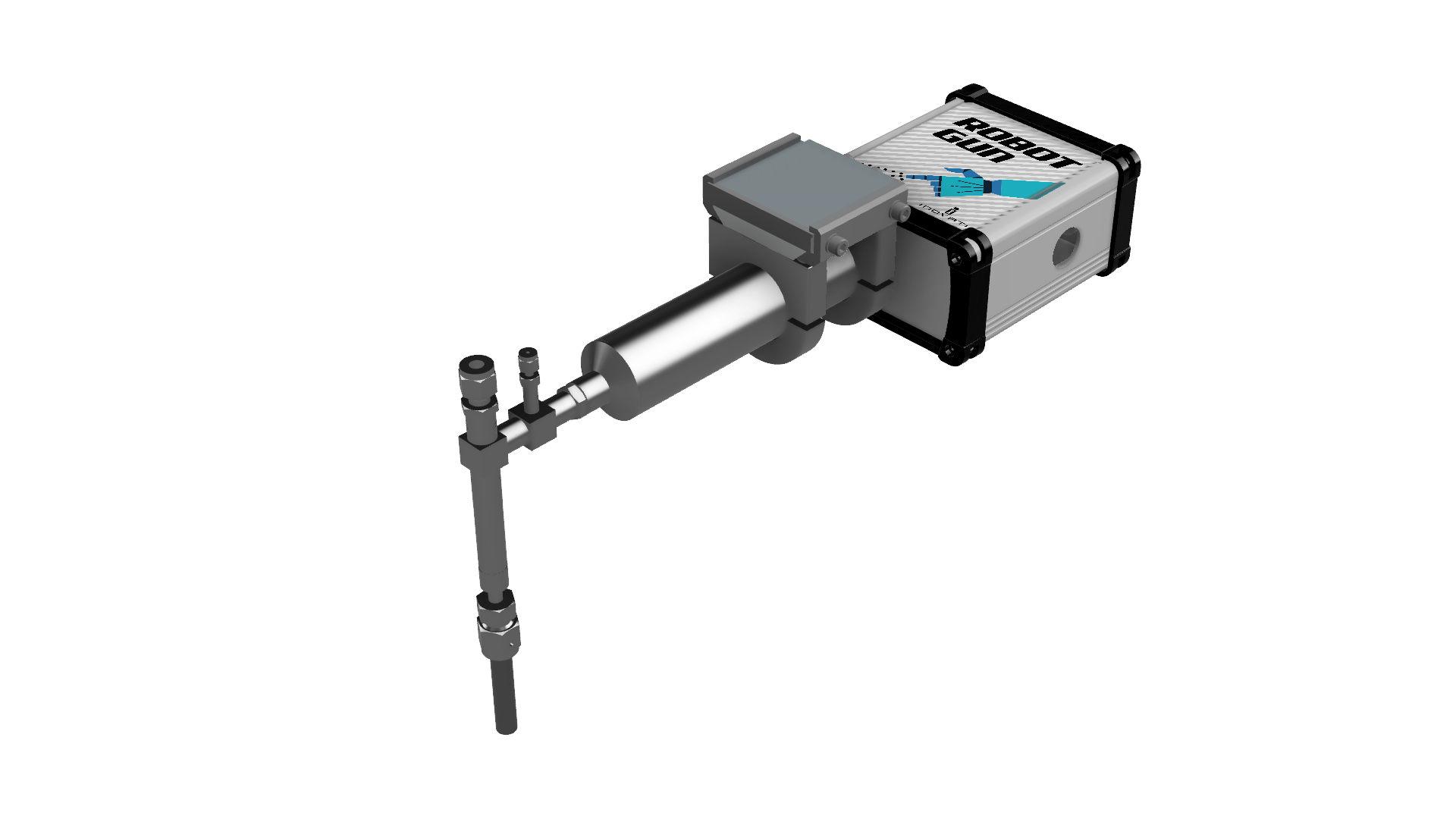

KM Gun

The KM Gun is the standard deposition tool for most applications. The KM Gun incorporates the heater, powder injection, and the patented friction compensated sonic nozzle. Features include:

- • High Performance PID Temperature Control Algorithm

- • Extensible Smart Capabilities

- • Rapid Pressurization and Gas Heat Up To Set Points

- • Plug Compatable and Interchangeable With Handheld Gun

- • Supports Raster, ID, OD and Programed Motion

- • Patented Friction Compensated Sonic Nozzle

Automation and Motion Control

The KM-HDR features a fully integrated six axis robotic arm and rotary stage allowing for accurate and consistent coating part geometries ranging from simple coupons to complex finished parts.

- • Fully Integrated 6-Axis Robot Arm

- • 7th Axis Rotary Stage

- • Extensible 8th Axis

- • Isolated Robot and Turntable Mounting Pedestals

- • General Purpose Motion Controls with HMI Selectable Motion Parameters

- • Quick Change Tooling For Mounting Fixtures and Sample Holders

- • Multi-Coupon Software For Process Parameter Development

- • User Specified Motion Programs

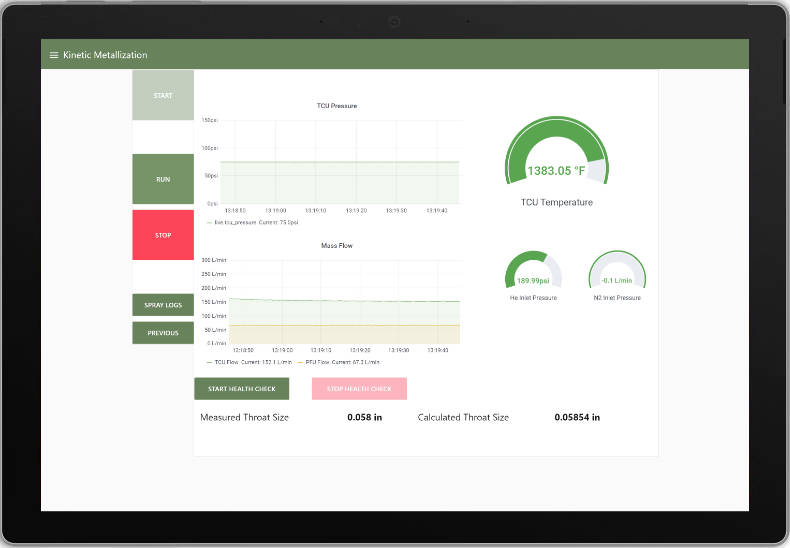

HMI

An all new user friendly interface for setting spray parameters, viewing/documenting results, and managing consumables inventory.

- • Live Display and Recording of all process parameters

- • Integrated Spray Log Database

- • Integrated Powder Inventory Database

- • Automatic QA/QC report generation including statistical analysis and graphical display of process variables

Powder Fluidizing Units

The latest generation of Inovati’s patented brush-sieve Powder Fluidizing Units (PFU) have been updated to improve accuracy, reliability, and simplicity of use. The KM-HDR system includes two PFU units that have been fully integrated into the spray enclosure for improved ease of access and powder handling. Other features include:

- • Easy Swap Hopper-Less Design

- • Powder Feed Rate: 0.5-100 g/min

- • Real Time Independent Process Control Of PFU

- • Powder Feed Rate Independent Of Gas Flow Rate

- • Patented and Additional Patents Pending